ISO-RC® Cold Sealing Compound SZ

• based on mineral oil and bitumen powder

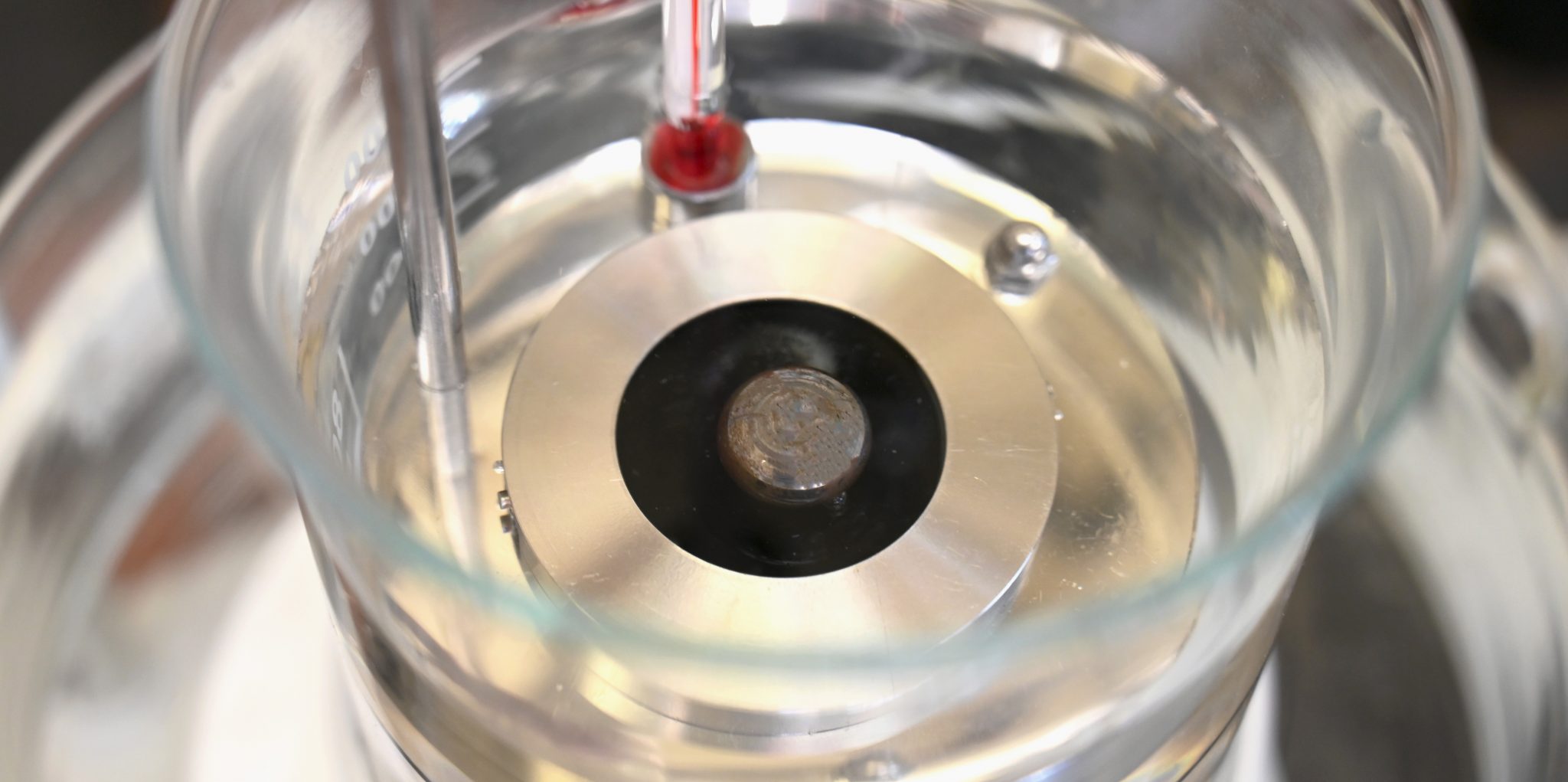

Double chamber bag ISO-RC® Cold Sealing Compound SZ

ISO-RC® Cold Sealing Compound SZ (according to DIN 57291/VDE 0291 Part 1/7.73) is a physically hardening two-component casting compound based on mineral oil and bitumen powder. As the bitumen swells, the product solidifies into a rubbery gel.

The product is preferably used for potting cable joints. The compound shows good adhesion to plastic and metal. Branch and connecting sleeves made of cast iron or stable housings made of impact-resistant plastic that can perform strain relief functions are suitable for pouring.

ISO-RC® Cold Sealing Compound SZ is free of halogenated compounds such as PCB, PCP etc. During processing no heating of the components is required and there is little volume shrinkage during solidification. Simple, non-destructive removal is possible by heating.

In addition, a reactive formulation with an increased softening point is available upon request.

Technical data

Colour

Black

Softening point

(Ring and ball, 14 days after mixing)

Approx. 40°C

Dropping point (Ubbelohde)

Approx. 55°C

Cone penetration (DIN 1995)

1d after processing (23°C)

7d after processing (23°C)

30d after processing (23°C)

Approx. 160 1/10 mm

Approx. 85 1/10 mm

Approx. 50 1/10 mm

Flash point

> 175°C

Specific contact resistance

Approx. 1,00×109 Ω×cm

Dielectric loss factor tan δ (20°C; 50 Hz)

Approx. 0,004

Dielectric strength

Approx. 20 kV/mm

Dielectric constant ε (20°C; 50 Hz)

Approx. 3,10

Ideal processing temperature

10°C – 25°C

Processing time (15°C)

Approx. 20 min*

Shrinkage

Approx. 1%

Storage and transport

Store in a dry and airtight, closed container at 10 – 35°C. Can be stored for at least 12 months in original sealed containers under the above conditions. Short-term deviations during transport and storage are acceptable.

Cleaning

To ensure good adhesion of the cast resin the customer should individually test the suitability of the involved surfaces. Possible pre-treatments like cleaning, activation processes (plasma process) etc. should also be taken into account. The contact surfaces should be free of dirt such as dust, grease or water. For cleaning we recommend ISO-RC® Degreaser for wipe degreasing or ISO-RC® Flux-Off + ISO-RC® Spraywash for spray degreasing (available in 400 ml spray cans).

Processing

The oil component is filled into the bag with bitumen powder. The proportions of powder and oil components are matched in a proper way. The mixture is carefully kneaded by hand for 3 minutes until a mixture without dry spots of powder is achieved. The ideal processing temperature is 10 – 25°C. In general, curing is delayed at lower temperatures and accelerated at higher temperatures. When using a double chamber bag, empty the corners well and knead for 3 minutes. Before casting, a homogeneous mass, free of streaks, must be obtained. Then pour immediately and do not scrape the mixing vessel.

The EC safety data sheet provides information on safety-relevant product properties.

Hardener component (containing diisocyanate): As of August 24, 2023, appropriate training must be provided before industrial or commercial use.